Program & Project Management

Fundamentally we exist for one reason: To accelerate our clients’ path to success. Our approach is simple; we help our customers uncover their explicit needs and put their interests first. We don’t stop working on the project until it’s right. And we’ll do whatever it takes to get there.

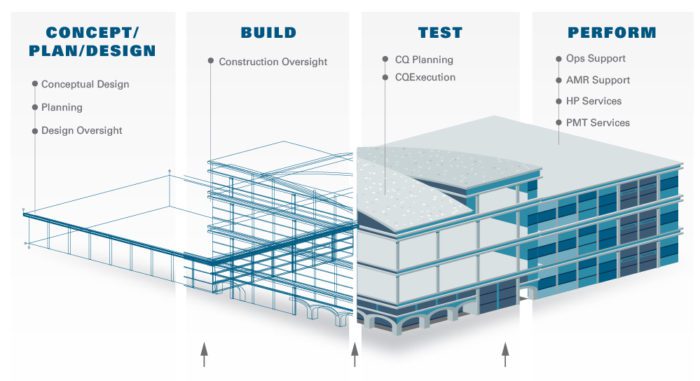

We bring top-tier expertise to every stage of a capital project, from creating comprehensive, detailed project plans to turning full-scale production operations into rigorous asset management, reliability, and sustainability activities. We are your choice:

- Because we establish and maintain a safe work environment.

- Because your project requires planned, managed, and documented high-quality testing to exacting standards.

- Because CAI has the bench depth and strength to meet aggressive schedules.

- Because you need high-performance teams working with your interests in mind.

- Because CAI understands the complex project environment that requires coordination among manufacturers, contractors, service providers, and client interests.

- Because mission-critical projects are complex, highly visible, and carry significant risk.

- Because CAI has extensive experience in the construction and commissioning of facilities for pharmaceutical and medical devices companies, applying rigor and process to managing a wide range of scope for successful delivery.

Philosophically and practically: We believe that quality, cost, and schedule can be mutually reinforcing – trade-offs are not necessary. Short-changing the focus on quality usually means problems down the road that can cost money and delay the schedule. But if quality is built in from the start, then both the project delivery and the operational efficiency objectives can be achieved with a much higher degree of assurance.

We believe that world-class facilities are successful due to planning and integration of these three areas: product/process/end-user requirements; people; and equipment/ automation/ facility technology. All our services focus on integrating these areas necessary for successful operations in mission-critical and energy-efficient facilities.

CAI PPM CAPABILITIES

- Risk Assessments

- Design Qualifications

- Design Reviews, Including Compliance-Related Design Reviews

- Value Engineering

- Quality Programs

- Scope Definition

- Cost Estimating

- Training in GMP Design & Standards

- Development of Project Team Organization

- Communications Plan Design

- Project Management Business Processes

- Conceptual Design & Facility Layout

- Selection and Oversight of Design Engineer

- Contractor/Subcontractor/Cm Prequalification and Selection

- Constructability Review Support and Site Logistics Planning

- Design And Implementation of Team Incentive Programs to Improve Integration

- Planning/Scheduling and Integration of Design, Construction, and Testing

- Project Controls (Cost and Schedule) Evaluation and Reporting

- Capitalization Of Assets

- Project Close Out

- Handover to Owner

- Shutdown Planning, Coordination, and Execution

- Team Training and Human Performance Improvement

- Human Error Reduction

- Maintenance Reliability & Production Optimization Program

- Total Productive Maintenance & World Class Maintenance Consulting

- Sop Reviews and Training Program Development

- Program Team Performance Evaluation

- Lessons Learned

PROGRAM AND PROJECT MANAGEMENT INTEGRATION

PPM focuses on the ‘White Space’ between the program elements or project functional elements to integrate and synergize the program/project.

Friction and non-productive conflict waste resources and cause suboptimal output in your program.

Program & Project Leadership is the solution.

CONTACT OUR EXPERTS

Erik Adams, MBA, PMP

Global Director, Program & Project Management

erik.adams@cagents.com | (757) 510-4654